Video Time and Motion

Lean Operations Delivered with Video Timer Pro

Watch Videos: VIDEO TIME AND MOTION

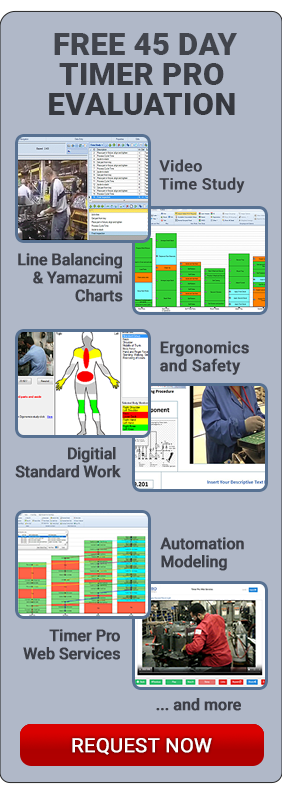

Timer Pro Professional’s Video Time and Motion module is the one tool that those involved in lean initiatives, process analysis, process improvement and lean training should not be without. It will save hours of tedious manual effort beginning from the very first time it is used.

Timer Pro Professional now offers clients Video-based time and motion analysis for your lean operation initiatives including:

- Encouraging operator involvement

- Identifying and documents non value added activities

- Isolating and create training recordings of best practice methods

- Integrated work balancing with drag and drop process modeling

- Creating standard time libraries based on best practices.

The package also includes PDA and Excel software modules for mobile real time data collection.

Video Time and Motion accurately documents and times any task while simultaneously isolating the non-value added work content. Video supported analysis creates an unchallengeable history of the current process state.

Select best practice clips for training the future process state. Feeds into your value stream mappings.

Easily Time All Process Related Activities

Each and every task observation can be instantly replayed for review and analysis, Best practices can be identified, isolated and consolidated into a new video presentation of the desired future process state the ideal solution to your training needs.

The video module includes powerful integrated task timing capabilities including slow motion, fast motion, timed jumps, instant rewind, side by side comparison playback completely eliminating the need for expensive time stamping video and players.

Even the most inexpensive, basic digital video cameras provide excellent quality input for the Video Time and Motion module.

Share Your Data Throughout Timer Pro

Output from the video analysis can be easily shared with other interested users and can be passed directly to Timer Pro’s :

- Work balancing module with access to drag and drop capabilities between task plus optimization by number of operators, production or takt time. In seconds you can see and quantify the effect of removing non-value added activities on throughput to achieve your lean production goals

- Company specific standard data libraries for repeated use by staff in lean teams, estimating, quoting and design

- PDA and Excel based time study modules for use in mobile real time data collection

- QuickTimes module for methods analysis and improvement using the included predetermined standard time dataset.

Standard Excel exports also support value stream maps using Visio and eVSM applications.

Google Unwanted Software Policy Compliance Statement

We hereby attest that the software application offered here is developed, owned and distributed by us for the purposes of process measurement to support your continuous improvement initiatives; will not affect the performance of your system hardware or change any system settings; is easily completely removable from your system; does not collect or transmit any private information in any form; is not bundled with any other software; is free of malware.